Professor Lee Oh-joon's Team Develops Dual Ultrasound Diagnosis System for Water Pipes

- Writer :대외협력팀

- Date :2024.07.30

- Views :768

Artificial Intelligence Professor Lee Oh-joon's Team Develops Dual Ultrasound Diagnosis System for Water Pipes through Global Joint Research

- Simultaneous measurement of corrosion and water quality of water pipes… Published in Nature's sister journal <npj Clean Water>

The Catholic University of Korea's research team of Artificial Intelligence Professor Lee Oh-joon, Kim Min-seo, a senior student majoring Information and Communications and Electronic Engineering and Jeon Hyun-joo of Korea Institute of Atmospheric Prediction Systems developed a system that can simultaneously measure corrosion of water pipes and water quality inside the pipes through global joint research with the team of Biomedical Engineering Professor Lim Hae-gyun of Pukyong National University and the research team of Dr. Hwan Ryul Jo from Flowserve Corporation in the US.

The paper covering the results of this research, 'Internal pipe corrosion assessment method in water distribution system using ultrasound and convolutional neural networks', was recently published in Nature's sister journal <npj Clean Water> (IF: 10.4, JCR 1.6% in Water Resources).

Iron oxide deposits generated by pipe corrosion can contaminate water, causing serious health problems such as gastrointestinal infections, skin problems, and lymph node complications, and if the pipe wall is weakened by corrosion, it can cause leakage or rupture. The risk increases, which can lead to increased repair costs and water supply interruption.

Accordingly, a non-destructive and continuous corrosion monitoring evaluation method has been required to protect water quality and extend the life of pipes by early identification of the pipe condition and conducting appropriate maintenance. Existing corrosion evaluation methods often require damage to pipes or system shutdowns, which has limitations that lead to economic inefficiency.

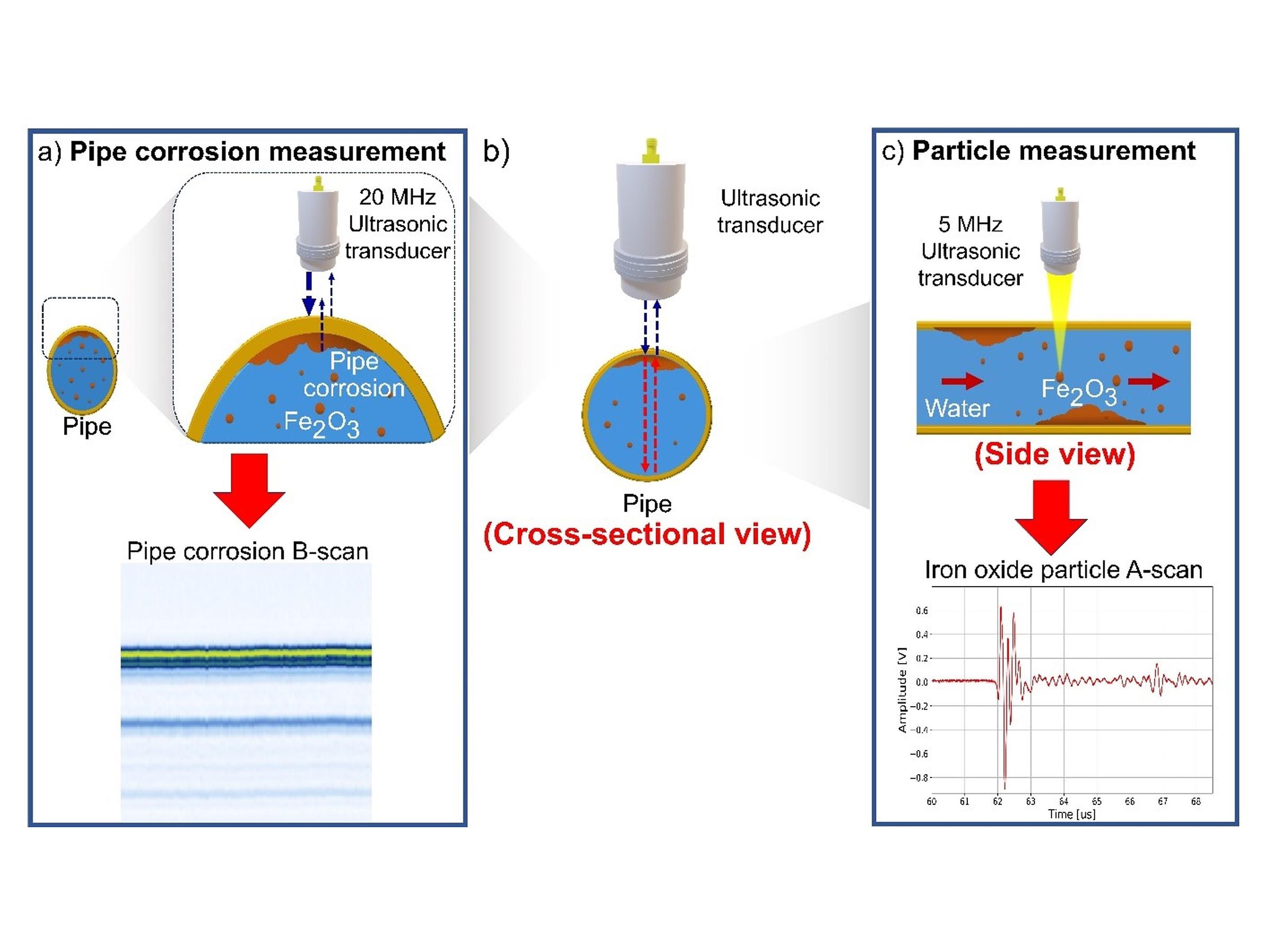

The research team developed a dual diagnostic system that enables non-destructive and continuous monitoring using ultrasound and artificial intelligence. Using a high-frequency ultrasound microscope (SAM), they successfully monitored the degree of pipe corrosion by generating high-resolution pipe thickness images. At the same time, they successfully measured the concentration of iron oxide in water by analyzing the ultrasonic signals inside the pipe using a convolutional neural network (CNN).

As a result of the study, all pipes with a thickness reduced by 69~80μm due to corrosion were measured using a high-frequency microscope, and the error range was within 5%. In addition, when the concentration of iron oxide inside the pipe was classified using CNN, it showed a high accuracy of up to 99%. If this dual diagnosis system capable of pipe corrosion and water quality analysis is utilized in industrial sites, efficient and precise pipe infrastructure management is expected to be possible.

The research team conducted this research through BK21 Four, the National Research Foundation of Korea's Excellent Young Researcher Support Project, the Regional Innovation Leading Research Center (RLRC), and the Excellent Researcher Exchange Support Project (BrainLink), and published a paper in <npj Clean Water> on July 13.